2019.10.07 (Mon)

BLOG

Brushcutter blade manufacturing process

Hello!!

This is SANYO METAL which is a manufacture of a variety of cutting blades for agricultural,

gardening and horticulture use as you already know!!

There are various kinds of blades for cutting grass.

We introduce the brush cutter blade (Metal blade) manufacturing process.

Press process

At first, outer diameter, hole and carved seal is manufactured by pressing.

Material is SKS-5

SKS-5 has be added Ni (nickel) and Cr (chromium) among alloy tool steels.

SKS-5 is the steel made in Japan with excellent durability and corrosion resistance.

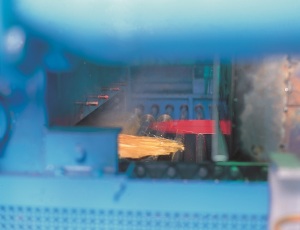

Hardening and Tempering process

Next, hardening and tempering are performed.

By tempering after hardening, the steel structure becomes martensite changes into a strong organization called. Durability and toughness are created to steel.

Our company has own furnace, so the hardness is managed accurately.

It is hard to break and finished to the optimum hardness with durability.

Put an edge process

Then blade edge is made by grinding.

It is filled with the know-how of the blade manufacturer such as the angle and how to sharpen.

Finally it will be packaging,

Before that, we inspect all products to deliver safe products to you.

We do not hesitate any effort to ensure safe use by our customers.