High quality and safe blades produced in the integrated production system within the company

As a manufacturer of cutting tools, Sanyo is dedicated to safety and make it a top priority with each product. In addition to impact testing machines conforming to ISO11806, we have in-house a number of testing facilities such as impact durability testing machines with a force of 5 kgf over 200h / 100,000 times, sharpness testing machines, and bend testing machines. We promise quality, safety and security with all of our products through our quality control system which is recognized by leading brush cutter makers all over the world.The 10th Excellent Product Safety Award for Companies in FY 2016, hosted by Ministry of Economy, Trade and Industry Commercial Distribution Safety Inspector's Award

Official organizations recognized the safety measures of Sanyo Metal Works.

Ministry of Economy has publicly asked companies who engage in product safety and strictly examined their product safety activities of entire company, then, the award is commended for the company’s outstanding achievement in Product Safety Measure.

Award-Winning evaluation : Efforts for ensuring safety and quality through integrated system from development to production Efforts for providing the users with operating instruction and precaution Efforts for improving Product Safety with machine manufacturers.

Comments from president, Terumasa Gohonjo : We, Sanyo Metal, have been making efforts as a company who provides the customers with safe products and reliable service. To make it possible, we dedicate the development and manufacturing of high quality blades through educational activities and input of information for safety uses. We will continue making further efforts aiming the production of quality blades which everybody can use with safe and confidence.

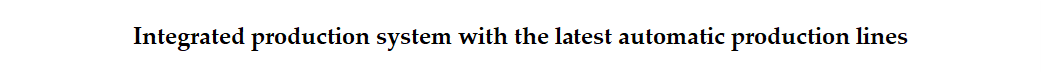

Production Facility

- Press machine with robot x16

- Automated grinding machine for Hedge trimmer x16

- Automated grinding machine for Twin blade x2

- Automated grinding machine for Brush cutter blade x8

- Automated grinding machine for TCT saw blade x7

- Rotary table type surface grinding machine x3

- Reciprocating type surface grinding machine x3

- Double head surface grinding machine x3

- Automated tip welding machine for TCTsaw blade x28

- Brazing machine for long blade by high frequency x2

-

- Numerically-controlled multi-function machine x9

- Numerically-controlled lathe x1

- Milling machine x3

- General purpose lathe x2

- Shot blast machine x4

- Laser marking press x1

- Automated packing machine x1

- ※TCT Saw blade = Tungsten Carbide Tipped saw blade

Thermal processing system

- Continuous quenching furnace x2

- Electric vacuum furnace with oil quench x1

- Electric tempering furnance x5

- Gas tempering furnace x1

- Laser hardening equipment x1

Inspection Facility

- Three-dimensional measuring system (Mitsutoyo)

- Metallurgical microscope

- Digital microscope VHX900 (Keyence)

- Micro Vickers hardness measuring system (Mitsutoyo)

- Rockwell hardness measuring systems (Mitsutoyo)

- Projector (Mitsutoyo)

- Magnetic defectoscope

- Brazing strength measuring system

- Unbalance measuring system

- Caulking strength measuring system (For measuring the strength of head pins)

- Bending strength measuring system (For ISO and JIS bending tests)

- Runout measuring instrument

- Cutting performance tester

- Oscillation tester

- Over-rotation tester

- Impact test machine (ISO11806)

- Durability test machine

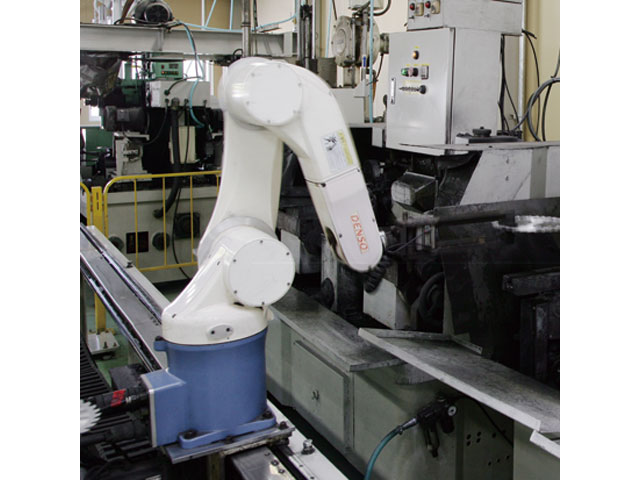

Design Facilities

- 2 two-dimensional CADs

- 3 three-dimensional CADs